We provide high-quality seamless steel pipes and pressure vessel plates for refineries, petrochemicals complexes and gas processing units with tailored logistics and services.

For these applications, Energy Projects is able to supply products in carbon and alloy steels in a wide dimensional range suitable for the toughest and most demanding environments and various applications.

We are able to offer pipe for sour service conditions with high corrosion resistance, for low and high-temperature service as well as for high-pressure applications.

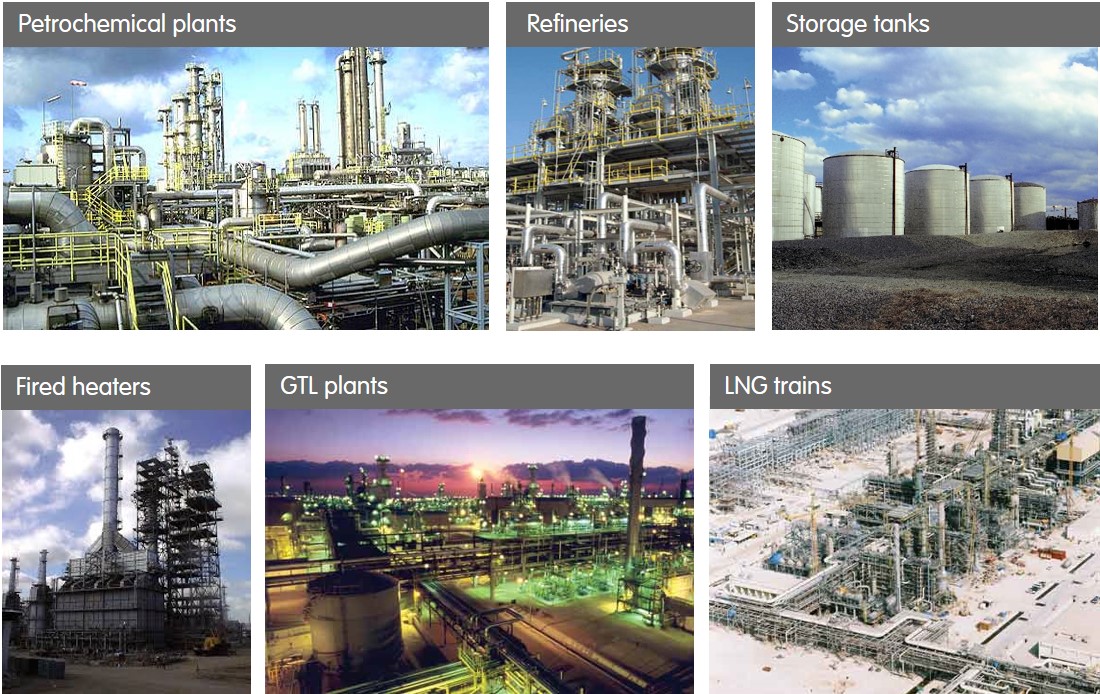

Our products are used in:

Alupur® combines the strength and fire resistance of steel with the corrosion resistance of pure aluminum. By using Alupur® operators can lower maintenance costs and increase safety.

It is a Type 2 aluminized steel which exceeds the ASTM A463/A463M standard. Compared to standard Aluminized Type 2 steels, Alupur® from ArcelorMittal has lower levels of silicon and iron which enhances its corrosion-resistance.

Alupur® has a multitude of applications in refineries, petrochemical facilities, gas power plants, oil storage facilities, liquid natural gas terminals, grain silos, and pipe cladding. In certain conditions, Alupur® is suitable for food contact applications and meets standards such as EC Regulation 1935/2004 (Europe)and NF A 36-712-2 (France).

Advantages:

ArcelorMittal’s Magnelis® metallic coating ensures optimal surface protection against long-term wear and tear.

Magnelis® is the optimal coating to protect against atmospheric corrosion, it:

Products

138,000MT plates, 101,000MT rebars

Customer

Dangote Oil Refinery Company

Products

3,252MT welded tubulars

Customer

Petronas

Products

4,864MT beams

Customer

Essar Projects